Pushing hard during the holiday break to get as much done as possible. This weekend I bent the longerons - a task that some say they have trouble with and others had no problem. Most of those that had no issues with the process didn't use the instructions (lay it on the ground and hit it with a hammer). Those that do use the hammer technique complain about the longeron looking like it was war torn. I used the dies to bend the parts and the vise and pipe process to open the angle. It took all day to get them finished but they came out fine. I should have the parts drilled out today and begin getting them ready for prime.

|

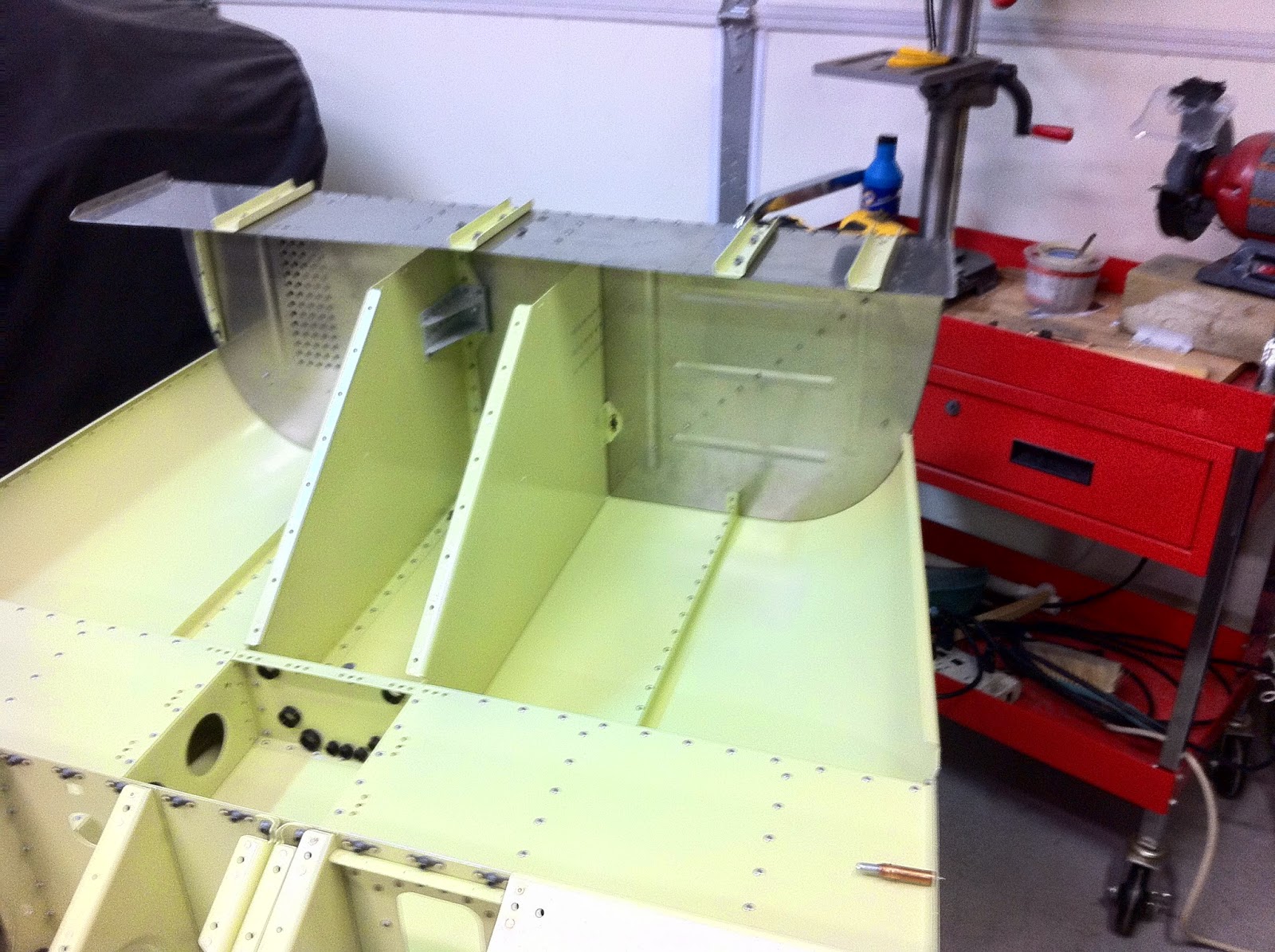

| Mocking up section 23 parts getting an idea where everything goes. |

|

| New batch of parts deburred ready for next steps. |

|

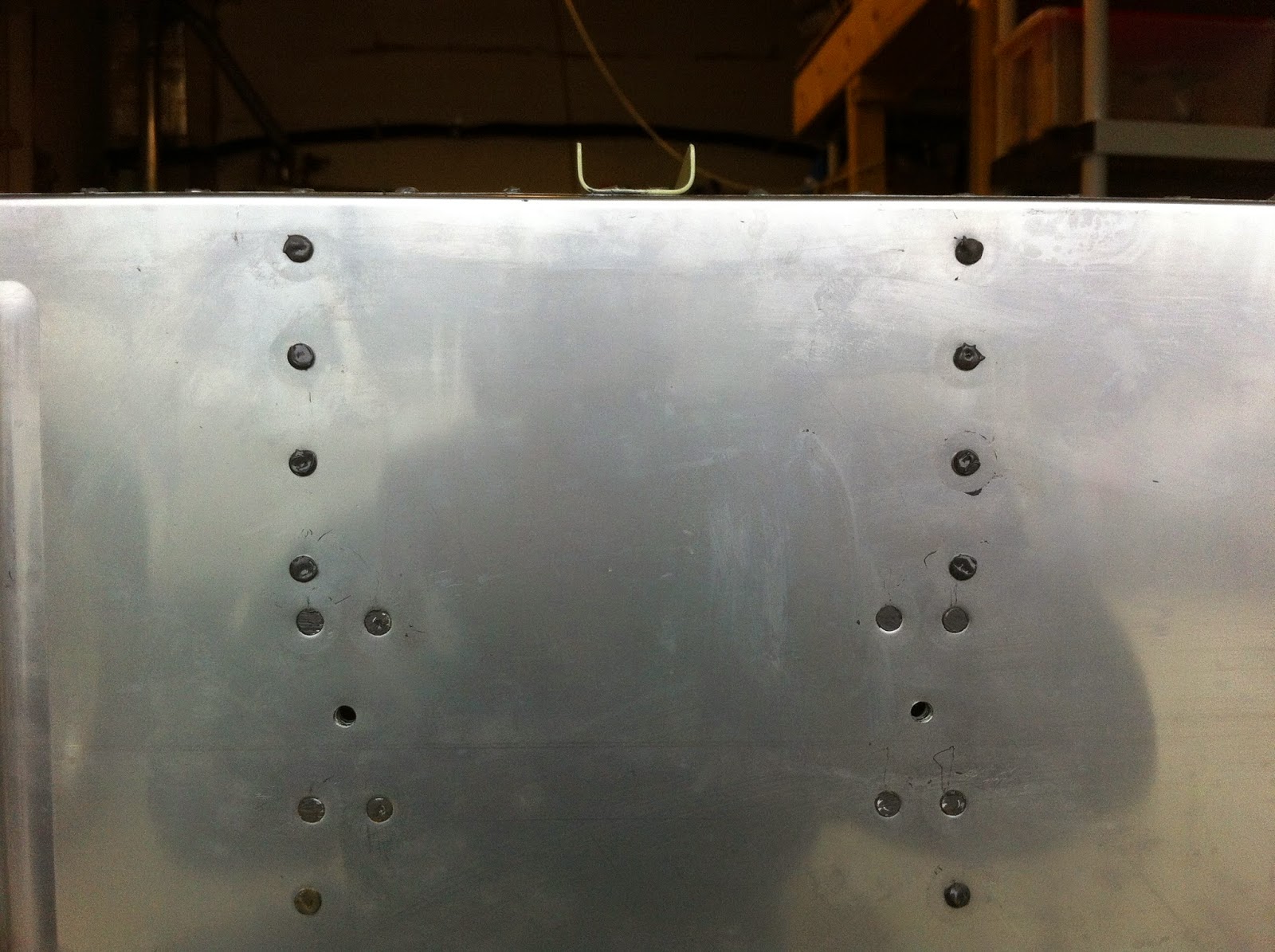

| Decided to pull the inspection covers off the Cessna and repaint them. It was badly needed but it's really just a peek at the entire plane - which I hope to paint in 2015. |

|

| The left longeron in place - lined up pretty nicely. |

|

| There are several (10) holes that need to be matched drilled at the doublers. |

|

| One down (bent) and one to go. The dies work well but can quickly over bend. |

|

| Here's the pair. They are close enough to pull into shape. |

|

| A shot of the left side. Shows the arm rest, the longeron and canopy shelf match drilled. Just clecoing these parts really adds strength to the structure. |